For the past week I've discharged and recharged more than a dozen NiMH batteries with my DIY smart battery charger, in the name of science of-course. The gizmo works fine and I'm happy with it. However, after analyzing all charging curves I came to realize that the cells got slightly overcharged. The charging process was systematically ending on -dV detection and not once did the dT event took place.

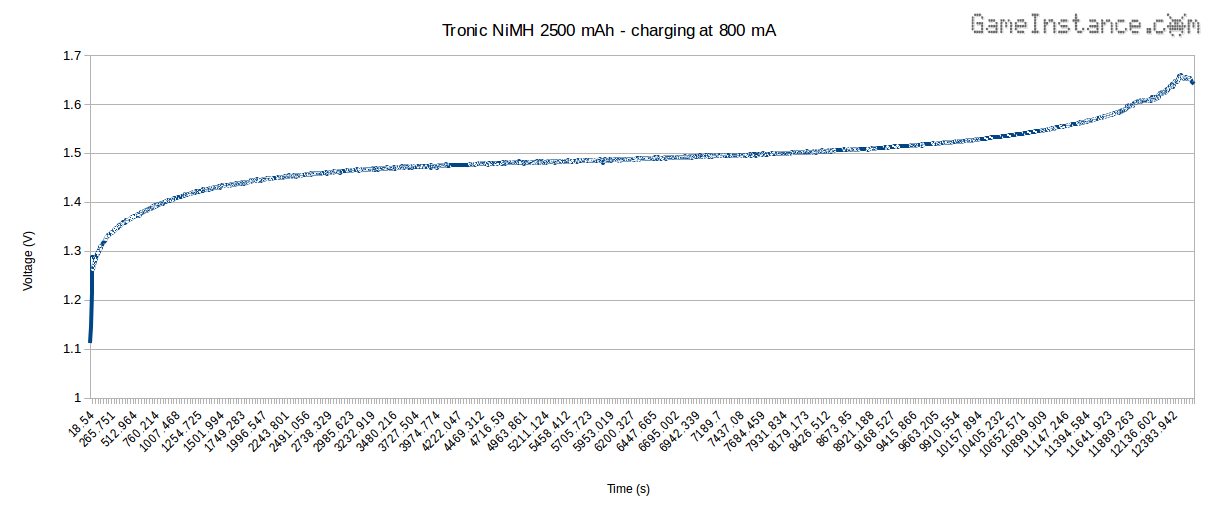

Tronic 2500 mAh cell charging at 800 mA - Voltage vs. Time

Tronic 2500 mAh cell charging at 800 mA - Voltage vs. Time

This article is about reducing the overcharge by making better use of temperature and its variation over time. Patterns have been observed during experimental recharging that led to a minimalistic, yet robust logic of detecting the end-of-charge. The method allows the cell to be recharged at lower temperatures compared with the -dV method and extends furthermore the service life of the battery.

State of charge and Heat

The current charged into a NiMH cell is used almost entirely by the chemical energy storage reaction that takes place on both electrodes. No heat is generated in the process unless the cell has a considerable internal resistance or the charge current is too high. As the reactants on both electrodes slowly saturate, the current that's no longer needed in the reaction gets gradually transformed in heat. The amount of heat produced increases until it reaches the maximum value, corresponding to the fully charged state. The temperature of the cell also increases until it reaches a value that represents the thermal equilibrium point of the cell. At that temperature the amount of heat radiated by the cell equalizes with the heat produced within.

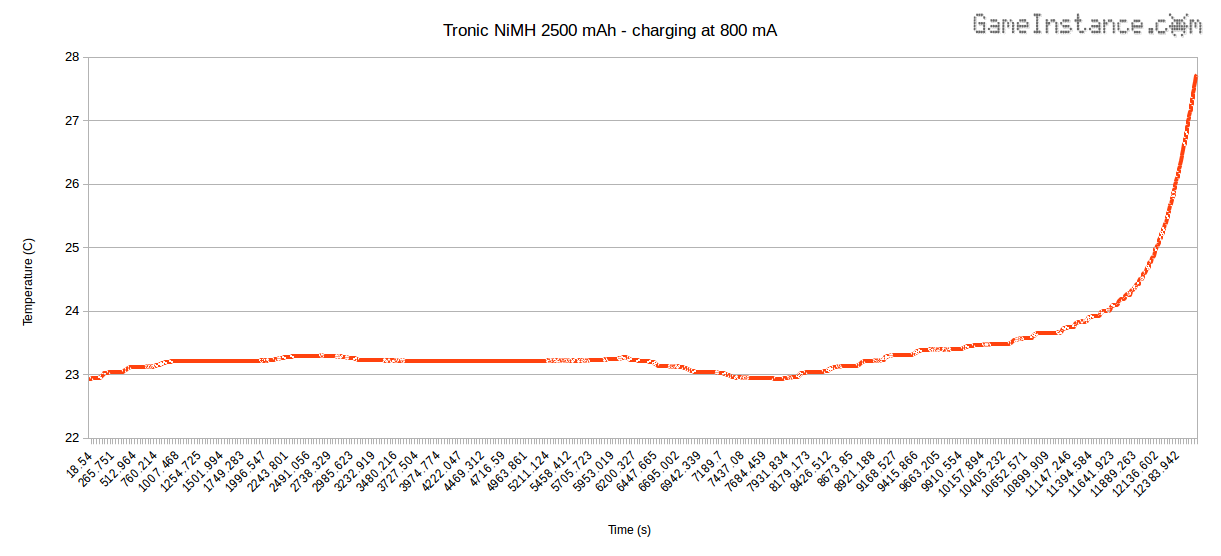

Tronic 2500 mAh cell charging at 800 mA - Temperature vs. Time

Tronic 2500 mAh cell charging at 800 mA - Temperature vs. Time

One could employ temperature thresholds in order to mark the end of charge. As the temperature goes above the set value, the charger will be stopped. However, this is not a robust detection mechanism considering the various situations under which a charger will perform - different ambient temperatures and different cells.

Temperature slope

or the rate of temperature increase can be determined and used with better results. It represents the speed at which temperature changes. For a constant temperature system the slope is zero and positive constant slope denotes a steadily increasing temperature.

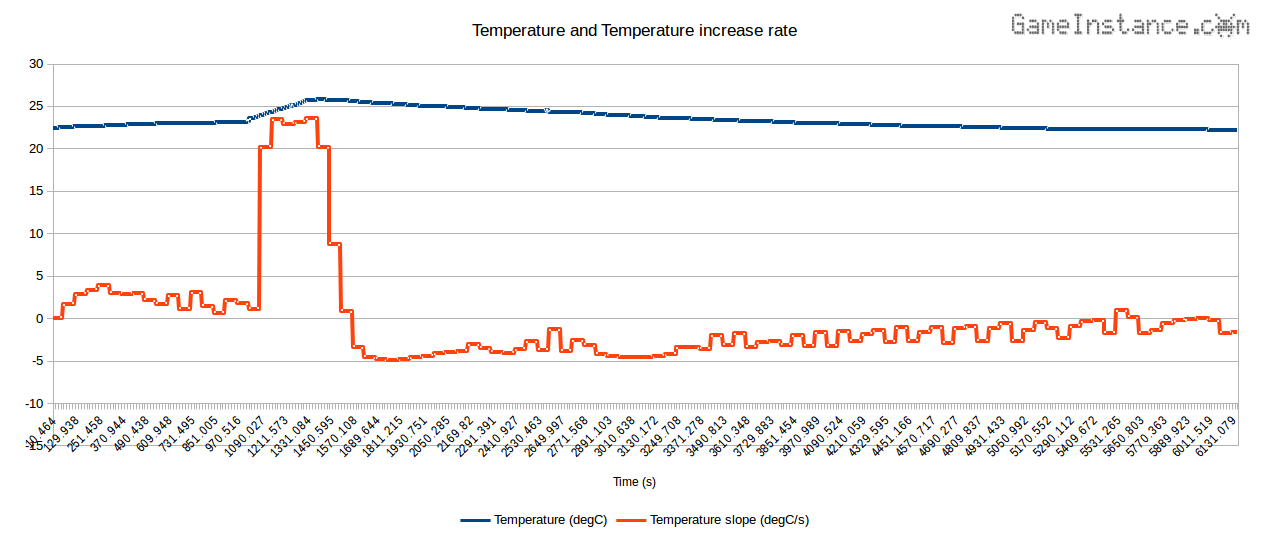

Experiments have shown

that heat radiated, conducted or convected from a system A to another system B will determine in B a step variation in the temperature slope, followed by a slow decrease. Consequently, the temperature of B presents a logarithmic increase. In this case, bringing a hotter object near the battery will have the same effect on the temperature and its increase rate.

NiMH cell heated for a brief period by an external source - Temperature and Temperature increase rate vs. Time

NiMH cell heated for a brief period by an external source - Temperature and Temperature increase rate vs. Time

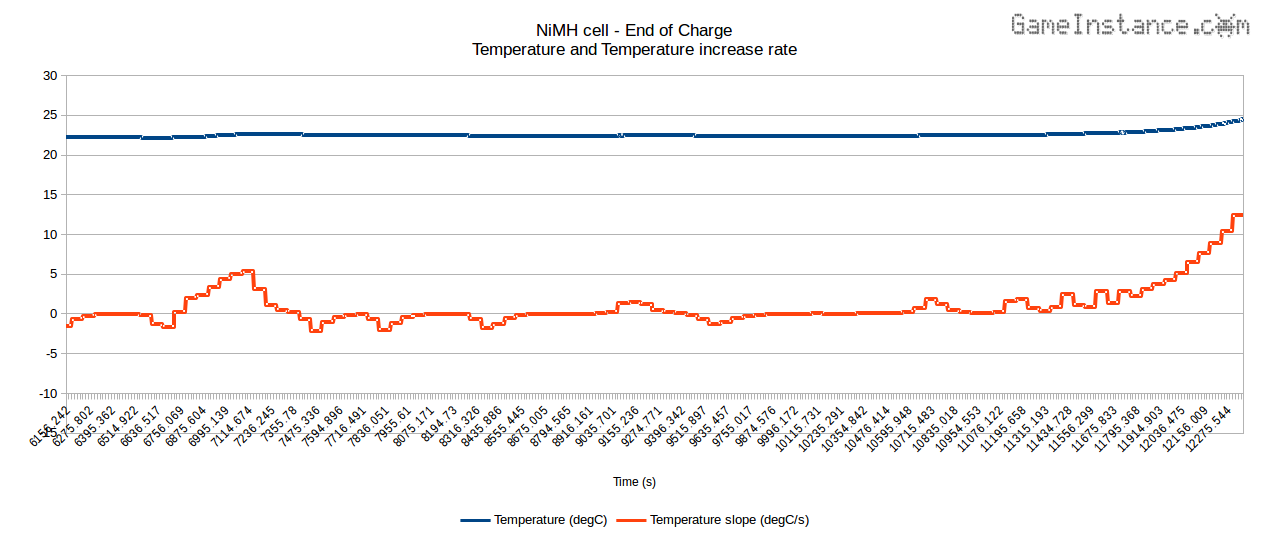

When a cell approaches the 100% of its capacity, the temperature slope increases gradually as opposed to the step change inflicted by the influence of an external hotter object. That is a valuable heuristic that can be exploited by the MCU in the charger project.

NiMH cell heated by overcharging - Temperature and Temperature increase rate vs. Time

NiMH cell heated by overcharging - Temperature and Temperature increase rate vs. Time

Using a sliding window to store temperature slope values read every minute, and logic that verifies all the samples in the sequence are positive and sorted, yields a charge ending event that's closer to the rated cell capacity. This reduces the overcharge by 5-15 % compared with the -dV method.

Bottom line

is that a charger will have to handle batteries of different SoCs, capacities and ages with no prior knowledge about them. As such, it has to make the best out of the information it has. -dV was good but the use of temperature rate of increase is better. However, both mechanisms should be used in parallel. If the later fails to trigger, the -dV eventually will.

However, the temperature slope is prone to generate more false positives than false negatives. To avoid that, the length of the sliding test window should be large enough. Experimentally, it has been chosen to cover the samples for 10 minutes. As the cause (heat generation) yields the effect (temperature increase) that needs to be monitored for a minimum amount of time (10 minutes) prior to a reliable decision, the charger will still slightly overcharge the cells. This does not include however the heat wave propagation time from the cell core to the NTC thermistor.